底部版权信息

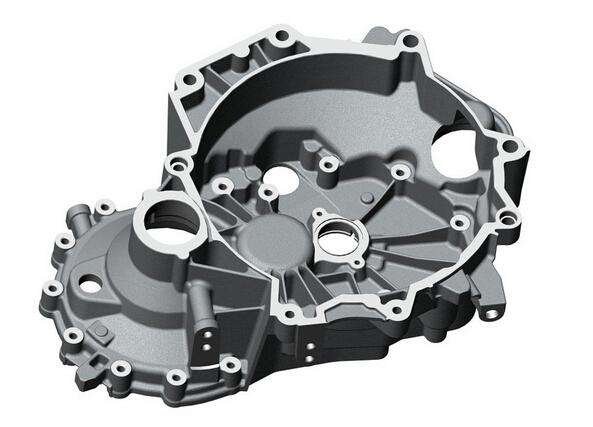

Analysis of the causes of foaming of die castings

2019/04/13

Page view:

Do you know why the die casting will foam? Wo Chi mold to help you analyze and analyze!

When the die casting has water marks, cold lines and hot cracks, the solution will penetrate into the crack during plating, and will be converted into steam during the barbecue, and the pressure of the atmosphere will cause the plating layer to foam.

(1) Thermal crack:

A. When the thickness of the casting is uneven, the stress is generated during the condensation process.

B. Premature ejection of metal strength is not enough.

C, the top force is uneven.

D, too high mold temperature makes the intergranular thick.

E. Harmful impurities are present.

(2) Water grain, cold grain:

During the filling process, the molten metal contact wall that entered first is prematurely condensed, and then the molten metal can not be melted into the condensed metal layer, forming a fold on the surface of the casting, revealing the strip. Lack of shape. The water pattern is usually in the shallow layer of the casting; the cold grain may penetrate into the casting.